The Rise of Cloud Manufacturing

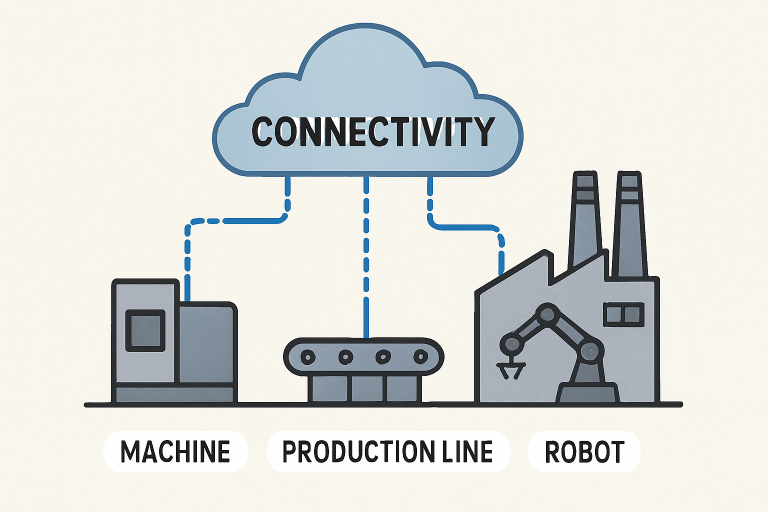

The manufacturing industry is transforming as digitalization reshapes workflows. Cloud manufacturing leads this change by integrating production processes, data, and management in the cloud. This shift moves manufacturers from paper routines to agile, data-driven operations accessible worldwide. Businesses increasingly rely on cloud based manufacturing software to orchestrate production, automate tasks, and support resilient supply chains—even in the face of global disruptions such as the COVID-19 pandemic.

Cloud-based tools help manufacturers become more agile by providing remote access and unified oversight of production, inventory, and machine health. These technologies enable real-time analysis, reduce bottlenecks, and ensure quicker product delivery. Adopting cloud solutions improves competitiveness in a shifting manufacturing landscape.

Key Advantages of Cloud-Based Tools in Production

Cloud manufacturing technologies enhance operational efficiency, cost savings, and flexibility for companies. They provide automated scheduling, real-time maintenance notifications, and advanced analytics to prevent downtime and minimize errors. Digital production practices improve throughput and quality, while data-driven insights enable proactive decision-making. Cost savings are achieved through process optimization, resource sharing, and rapid scalability. Agile companies can pivot to market shifts, expand into new product lines, and optimize existing offerings while maintaining low expenses.

Digital Collaboration and Real-Time Insights

Cloud technology enables real-time collaboration across departments and locations, reducing friction and accelerating response times. It provides dashboards, shared work orders, and digital blueprints, enabling stakeholders to coordinate effectively. This data allows teams to act on potential issues immediately, curbing disruptions before they become costly setbacks. Digital workflows facilitate cross-functional teamwork, shrinking lead times and bringing products to market faster. This integration supports sustainable growth and increases stakeholder satisfaction as organizations scale.

Overcoming Common Challenges With Cloud Manufacturing

Traditional manufacturers face challenges in transitioning to cloud manufacturing, including data security concerns, employee resistance, and disruption to processes. Effective change management strategies, including clear communication, role-based training, and scalable pilot projects, are crucial. Prioritizing workforce education and appointing digital “champions” can reduce resistance and improve outcomes. Industry leaders recommend phased deployments, transparent leadership, and tailored support for long-term adoption and investment returns.

Data Security and Trust in the Cloud

The shift to cloud-based manufacturing data necessitates robust security protocols like encryption, multi-factor authentication, and regular audits to protect sensitive information. Choosing cloud platforms that adhere to international standards, such as ISO and NIST, boosts trust among customers, partners, and regulatory bodies. Transparency about data governance practices, as recommended by industry sources like CSO Online, further enhances compliance.

Future Trends in Cloud Manufacturing

Cloud manufacturing is transforming the digital landscape, integrating artificial intelligence and machine learning to enable predictive maintenance, automatic quality inspections, and real-time supply chain optimization. IoT-connected devices and advanced analytics will deepen data integration, powering smart factories that self-adjust to maximize efficiency. This next generation of manufacturing demands workers with digital skills, prompting progressive organizations to invest in upskilling and ongoing education. Cloud manufacturing will drive operational improvements, support sustainability targets, and provide a competitive edge, allowing companies to weather evolving market demands.

Conclusion: Embracing the Digital Transformation Journey

The digital manufacturing revolution is accelerating, with cloud-based technologies playing a crucial role. Strategic investments in cloud manufacturing platforms lead to more efficient workflows, clearer collaboration, and stronger global market presence. With robust cybersecurity protocols and workforce training, successful digital adoption is easier. Cloud manufacturing is expected to remain the backbone of factory innovation and excellence.